Article Revised August 26th, 2022

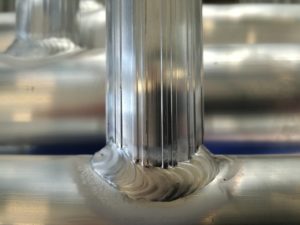

As a full-service precision sheet metal fabricator, EVS Metal offers a wide array of specialized manufacturing solutions in-house. One of these solutions is welding aluminum and stainless steel for metal fabrication. While this might seem simple at first, welding is quite a complex skill, and welders are generally required to attain several different types of certifications and endorsements per specific American Welding Society (AWS) standards.

As a full-service precision sheet metal fabricator, EVS Metal offers a wide array of specialized manufacturing solutions in-house. One of these solutions is welding aluminum and stainless steel for metal fabrication. While this might seem simple at first, welding is quite a complex skill, and welders are generally required to attain several different types of certifications and endorsements per specific American Welding Society (AWS) standards.

Types of Welding Certifications and Endorsements

AWS D9.1M/D9.1:2012 Sheet Metal Welding Code: All EVS welders meet at least the minimum requirements of the general AWS code.

AWS D1.2, Structural Welding Code – Aluminum: This endorsement covers four specific welding subject areas: material and design, fabrication, inspection, and qualification.There are many more endorsements available that allow specialists to perform certain types of welds. Our company makes a concerted effort to ensure that our welders are able to obtain the necessary training to take on any job presented to our company.

B2.1: The AWS specification for welding procedure and performance qualification.

There are many more endorsements available that allow specialists to perform certain types of welds. Our company makes a concerted effort to ensure that our welders are able to obtain the necessary training to take on any job that is presented to our company.

Specializations in Welding

Besides specific endorsements, there are also different types of welding styles for metal fabrication in which one can choose to specialize, such as spot and arc, both of which EVS Metal can provide. Each is useful in its own way:

Gantry- and platen-style spot welding (also known as RSW — resistive spot welding): a process in which two metal surfaces are joined by electric current resistance.

Arc welding, including TIG and MIG welding: TIG (tungsten, inert gas) welding utilizes a non-consumable tungsten electrode to produce the weld and argon or helium as a shield and is the preferred method of welding thin materials. TIG welding requires considerable skill and is a slower process than other forms of welding. MIG (metal, inert gas) welding utilizes a continuous wire feed as an electrode and an argon-based shielding gas (sometimes mixed with carbon dioxide) to produce the weld. As it’s semi-automated, MIG welding can be a faster process than others but isn’t appropriate for every application.

Additionally, there are near-constant advances being made in terms of welding technology — robotic welding for metal fabrication being one of the fastest-growing areas of specialty. Robotic welding completely automates the process, and although not the right solution for many jobs, the accuracy and speed can be difficult to match when used correctly.

Find out how EVS Metal’s experts can assist your company with its aluminum or steel welding needs by requesting a personalized quote online or by calling (973) 839-4432.