Metal Fabrication Solutions

Turret Punch Presses and Cutting Lasers

EVS performs precision sheet metal fabrication processes on a range of materials including steel, stainless steel, aluminum, and brass. Turret punching and/or laser cutting is the first step in the fabrication process with any of these metals in order to produce a finished part or product. The speed and accuracy of EVS Metal’s turret presses and lasers, including CNC-enabled machines, helps us maintain a competitive edge on part cost, and results in consistently high levels of quality. The ability to run unattended and the large capacity provided by our sixteen machines allows us to meet and exceed our customers’ requirements. A comprehensive, on-site training program guarantees the exceptional skill level of EVS’s machine operators.

Metal Forming and Bending

Our metal forming and bending department is equipped with the latest fabrication technology, including CNC-operated machines and those with automated bending robots. We utilize European-style press brake tooling for greater accuracy, longer tool life, flexibility and faster set-up time. EVS Metal’s 27 press brakes are networked to accurately store programs and speed setup of repeat jobs, utilizing Amada’s Bendcad software to program the brakes offline, further minimizing machine downtime and lead times.

Hardware Insertion

Our hardware insertion capabilities feature massive capacity, including 33 Haeger insertion presses, most of which are equipped with automated feeds to increase efficiency.

Metal Polishing, Graining and Deburring

To provide EVS customers with scratch and burr-free parts, we utilize state-of-the-art Timesaver© graining/deburring machines and an extensive array of tumbling and grinding equipment. From grained finishes to #8 mirror stainless, our highly-skilled techs can handle every surface metal finishing need.

CNC MACHINING / MACHINE SHOPS

Our ISO 9001:2015-certified machine shops in Austin, Texas (ITAR-registered) and Stroudsburg, PA are equipped with automated, state-of-the-art CNC machining technology for metals & plastics, including steel, stainless steel, and aluminum. Our staff of engineers imports 3D files (.sldprt, .prt, stp, iges, x_t) using the most recent version of SolidWorks, allowing our experienced machine operators to use these 3D models to program the equipment using MasterCam X.

As a result of the company’s investment in advanced machining technology, EVS is also able to perform secondary operations on precision sheet metal fabrications more efficiently to better serve our customers’ needs.

Overview of EVS Metal’s CNC Machining capabilities:

- Climate-controlled environment

- Work envelope: 50x20x20 vertical; 22x25x22 horizontal

- Precision tolerances of +/-.001 inch

- Run quantities from 5 to 2500 pcs

- High speed 15,000 RPM

- Renishaw probes for accurate tool placement

- Oldest machine 2009

- Newest machine 2021

- Materials machined include ferrous, non-ferrous and plastics

- 4 vertical CNC mills; 1 horizontal CNC mill; 1 CNC Lathe w\Live and 90-degree tooling

- Romer Arm CMM

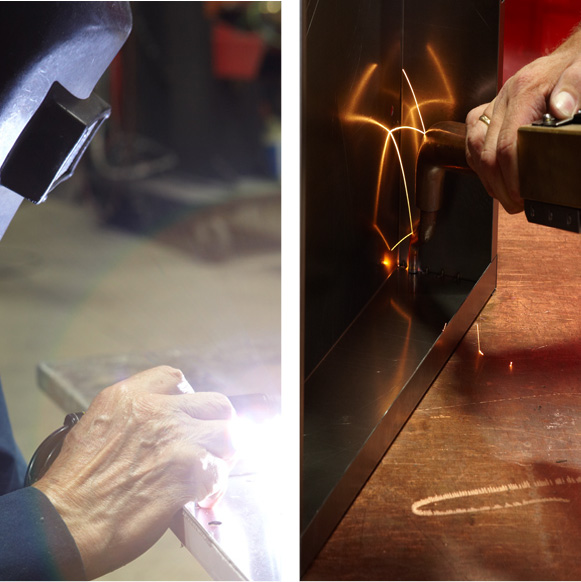

WELDING

From spot welding to GTAW and GMAW arc welding, our team utilizes state-of-the-art equipment to create precision welds and fabricated metal weldments for even the most complex fabrication projects. Discover the difference in product quality when utilizing the industry’s finest welders.

Overview of EVS Metal’s Welding Capabilities:

- TIG and MIG welding in all material, gauges, and sizes

- All welders are certified to meet, at minimum, the requirements of the American Welding Society D9.1M/D9.1:2006 Sheet Metal Welding Code

- Welders are currently certified to AWS codes such as D1.2 and B2.1. If we do not have a welder certified to a specific code, our welders can quickly certify to that code in order to handle any project

- In-house precision fixture design and fabrication

- Experts in large precision frame and enclosure welding

- Robotic welding in steel, stainless steel and aluminum

- Gantry-style spot welding equipment provides the ability to work with heavier and larger parts

- Platen-style spot welding equipment provides efficient spot welding of larger parts as well as the ability to provide highly-cosmetic spot welds

- Spot welding in most materials and gauges

METAL FINISHING

Unlike most precision metal fabricators, EVS Metal has the ability to handle value-added finishing services such as wet paint and powder coating sheet metal finishing operations for fabricated metal parts, all in house. This allows us to better control quality, cost and lead times.

EVS Metal – New Jersey:

Fully-Automated Powder Coating Line

- Three-stage gas-heated spray washer

- Final fresh RO Halo Rinse

- Reverse osmosis system to fill the phosphate and rinse tanks

- Gas-heated water dryer/powder bake oven

- 460′ monorail conveyor system

- Nordson Versa-Coat automatic powder spray booths with six-gun reciprocating automation

- Direct Color Systems Direct Jet UV Color 7200z Printer 23.8″x48″ Printable Area

- (3) Nordson manual spray guns

- (4) Silk screening stations

EVS Metal – Texas:

Fully-Automated Powder Coating Line

- Three-stage gas-heated spray washer

- Final fresh RO Halo Rinse

- Reverse osmosis system to fill the phosphate and rinse tanks

- Gas-heated water dryer/powder bake oven

- 470′ monorail conveyor system

- Nordson Vantage RCM 8000 automatic powder spray booth with Vers-Spray II six-gun reciprocating automation and i-control

- AZO sieve reclaim

- 3 Nordson manual spray guns

EVS Metal – Pennsylvania:

Fully-Automated Powder Coating Line

- Three-stage gas-heated spray washer

- Final fresh RO Halo Rinse

- Reverse osmosis system to fill the phosphate and rinse tanks

- Gas-heated water dryer/powder bake oven

- 470′ monorail conveyor system

- Nordson Vantage RCM 8000 automatic powder spray booth with Vers-Spray II six-gun reciprocating automation and i-control

- AZO sieve reclaim

- 3 Nordson manual spray guns

EVS Metal – New Hampshire:

Wet and Powder Coat Finishing

- Four prime and finish coat paint booths

- Waste2Water model VIPIR ESD V01 pretreatment and recycle module

- Waste2Water above-ground VIPIR 6X12 wash pad, ESD V23

- Clemco Ind. BKP720-1200RDC blast room with 500 LB turntable

- Wisconsin EWN-88-7G oven

- Ability to apply CARC to MIL-DTL-53072C

Our Automated Powder Coating Lines

EVS Metal’s investment in four automated powder coating lines across all four facilities signifies a commitment to delivering unmatched quality and precision in metal fabrication. These advanced coating lines bring significant benefits to customers:- Consistency: Automation ensures uniform and consistent powder coating application, eliminating variations and imperfections.

- Efficiency: These automated lines significantly reduce production time, enabling quicker turnaround for customer orders.

- Cost-Effectiveness: Efficiency leads to cost savings, allowing EVS Metal to offer competitive pricing without compromising on quality.

- Environmental Responsibility: The powder coating process is environmentally friendly, aligning with sustainable and responsible manufacturing practices.

- Enhanced Aesthetics: The automated lines deliver a smooth and attractive finish, elevating the final product’s visual appeal.

- Improved Durability: The precisely applied powder coating enhances the product’s resistance to wear, corrosion, and harsh environmental conditions.

Additional Metal Finishing Services

EVS Metal utilizes the expertise of several certified local resources for finishing, including services such as metal plating and anodizing. These additional capabilities reinforce our commitment to being an end-to-end provider, ensuring quality and consistency while simplifying our customers’ purchasing process.

ASSEMBLY / INTEGRATION

While best known as a leading precision sheet metal fabricator, our capabilities stretch far beyond. As a vertically-integrated manufacturer, we offer an extensive suite of assembly and integration services across diverse industries. From military and defense to power supply, energy, medical device, warehouse autmation, robotics and data center components, we’re your partner in fabrication excellence.

- Mechanical Assembly: Assembling custom-fabricated parts into subassemblies and chassis by mechanical means such as fasteners or rivets, or welded means such as spot welding or arc welding. Assemblies may be small or large, and can include subassemblies or completely assembled products.

- Assembly and Integration of UL-Certified Products: EVS currently builds many products that have been previously UL Certified by our customers in their own shops. Our engineers and production supervisors work with UL to ensure our New Jersey metal fab facility remains certified to build and label all products as our customers would do in their own facilities. This includes NEMA-rated electrical enclosures.

- Active Electronics and Software Installation: This process involves integrating active circuit boards, hardware and software to the electromechanical assembly. Full functionality, performance and diagnostic testing is completed to ensure desired functionality. EVS is also able to perform all electrical safety testing including: AC/DC hipot, insulation resistance, ground continuity and leakage testing.

- Electromechanical Assembly: Joining of electrical components into the mechanical assembly, including the installation of fans, cables, wire harnesses and power supplies.

- Box Build and Logistics: Complete build-to-order assembly and/or integration with test processes that build a finished product for an OEM customer or end user. All logistical support and supply chain management services are provided including direct shipment to the end customer.