EVS Metal is pleased to publish another installation in our ongoing series of spotlight articles highlighting employees and their departments. We hope these help illustrate EVS’ capabilities as a manufacturer and precision sheet metal fabricator, and the value our people bring to the table each and every day.

This week, we’re speaking with Greg from our New Jersey fabrication facility.

Q&A with Greg, Metal Forming Engineer, EVS Metal Fabrication, New Jersey

EVS Metal: How did you become interested in a career in the metal fabrication industry?

Greg: Honestly? By accident! As an immigrant with very limited English language at that time, my chances to work in any office were slim. I had a family member who was a lead in the brake department and he helped me get my first job in metal fab.

EVS: Describe your career trajectory — how did you start, any specific education/training/experience, what different positions have you held etc. — that led you to your position as a metal forming engineer.

Greg: I started at Pilot (later known as Flextronics, now FLEX) as a press brake set up specialist and operator, then quickly became a prototype set up man. After the company closed, I got the job at EVS Metal and have worked here ever since. I started at EVS in the same position, then became a Lead in the forming department. At this same time, I was introduced to offline programming (I completed Dr.ABE training at an Amada facility) and automation. The mechanical engineering degree I completed back in Poland gave me a perfect base for this type of work, and it’s the reason why it came very easily to me.

EVS: How long have you been with EVS?

Greg: 16 years.

EVS: What does a typical day at EVS look like for you?

Greg: Scheduling work in the brake department including robotic brakes, overseeing work in process, programing brakes with Dr. Abe software, programming robots with AstroCam and AR-CAM software, setting up robots, looking for new robotic forming possibilities, constant improvement of existing processes, training, troubleshooting, assisting designs, reviewing quotes, testing tooling and bend deductions, and soft tooling design.

EVS: What do you like most about your job as a metal forming engineer?

Greg: I like that it’s always challenging; I enjoy having the opportunity to constantly learn new things (software, machines). Plus, working with robots is always interesting.

EVS: How would you describe EVS’s company culture?

Greg: EVS is a fast-paced company with a great team and lots of opportunities. Our management team invests in state-of-the-art equipment and software, which gives us the ability to easily adapt to the current market in terms of customers’ changing needs. We are also provided with multiple learning/training opportunities that allow us to advance our careers.

EVS: How many people are involved with forming processes overall at EVS?

Greg: We have 7 press brake operators, 1 assistant for robots, and I take care of programming and robotic press brake setups, so 9 total.

EVS: Are there different specialties within metal forming?

Greg: Typically, yes. Usually, there is a programmer, set-up specialists, and operators. Different skill levels within specialties as well. At EVS NJ every operator sets up the machine by himself because the programs I create with Dr.ABE_bend take a lot of the forming difficulty away from operators, leaving them to do more with fine adjustments instead.

EVS: Are there any certifications or specific knowledge areas required to become an expert in metal forming?

Greg: Definitely strong math — especially geometry and physics; mechanical understanding is a must. Being open-minded, detail-oriented, creative, very good at troubleshooting, and problem-solving. Someone who likes a challenge and is able to think “outside of the box” would be a good candidate.

EVS: What types of systems/software/machines are used in forming, and what are they used for?

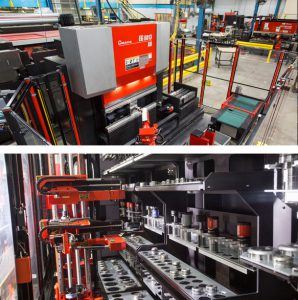

Greg: We use Sheetworks and AP100 system from Amada with Dr.ABE, Astro-Cam and AR-CAM software to program our manual and robotic press brakes. Our machines are:

- Amada HDS 1303 x2: most difficult parts (big opening and 10’ bed)

- Amada FBD1253 x2: medium/high difficulty parts

- Amada FBD1025 x2: smaller/medium parts, medium-difficulty parts

- Amada HG8025: smaller/medium parts, medium-difficulty parts

- Amada HG1003 ATC: prototype work

- Astro100ME-8025: x3: longer runs, medium-sized parts

- Astro100MH-1253: longer runs, bigger parts

- Amada EG6013-AR: small parts robot for smaller and larger qty.

EVS: Are there common products that are fabricated via forming?

Greg: There are a wide variety of products that can be fabricated via forming. From simple brackets, boxes, and electrical panels, to super-complicated chassis and assemblies.

EVS: What are the most common forming processes completed at EVS?

Greg: Most common are bottom bending, air-bending and bumping.

EVS: Are there any special metal forming processes available at EVS that are fairly unique for the industry or of special interest?

Greg: Rolling, bumping, wipe forming, embossing, flattening, benching, air bending, bottom bending — we are able to complete a number of processes between our four facilities.

EVS: What was the most complex forming challenge you have encountered?

Greg: The most complex metal forming challenges are always related to robotic forming. The actual bending is not always the hardest part. Picking the part up, regripping or stacking them is a super difficult task at times. As for manual brakes, the complexity usually involves finding creative ways to form parts that would generally require custom tooling with standard tooling, or forming complicated parts on a single multi-staged set up to achieve a complete part (the time we did a 30 bender for one of our customers with multiple radiuses comes to mind here).

EVS: What was the largest forming project that EVS has completed, to your knowledge?

Greg: The latest project that comes to mind was a retail SIM card kiosk prototype for a global telecom company. It involved a large number of parts and we were given a super-short lead time. None of it would have been possible without our Amada software (Sheetworks, Dr.ABE_Bend).

EVS: How do lean manufacturing practices influence your work?

Greg: Lean practices reduce waste, so it’s important to emphasize the production of more products with fewer (or at least no extra) parts whenever possible. This means our operators need to be on their game at all times; we calibrate machines carefully to ensure there are fewer bending errors in the first piece. In a perfect world, the first piece fabricated would be exactly to spec.

EVS: What types of lean practices do you use in the metal forming department?

Greg: We produce smaller batches of parts and replace old equipment with new automated or half-automated self-set up machines that cut waste and improve efficiency significantly. We also calibrate machines very precisely to eliminate error and set up-pieces. We are constantly working to improve current processes and switch to more automated processes whenever possible.

EVS: What do you see as the benefits of lean practices in metal forming?

Greg: Thanks to lean practices we have been able to create a more profitable business by eliminating waste and improving efficiency. We are able to focus on customers’ needs as well as overall product value.

EVS: What are the specific challenges of using lean practices in a high-mix, low volume environment?

Greg: Challenges are mostly related to training operators to be more efficient with setups. Using fewer or even no extra parts can be very challenging.

EVS: How do you see the metal fabrication industry growing or changing over the next few years? How do you see EVS Metal changing to accommodate/address these things?

Greg: Sheet metal fabrication is quickly moving toward automation. It’s the only way to keep production costs down and remain competitive with China. It is also becoming more and more difficult to find experienced/skilled workers in this industry, which has also had a huge impact on metal fabrication and manufacturing. However, EVS prioritizes investing in software/automation/advanced machines, and this often allows for a single, experienced operator to team with fairly inexperienced assistants to get the job done efficiently and cost-effectively.

EVS: Anything else you’d like to share about your position/responsibilities/department?

Greg: There are a number of areas that have changed as more advanced technology has rolled out. Back in the day, most projects were designed from more, but less complicated, parts that were welded/assembled together, rather than the very complicated, but mostly one-piece, construction you see today. That places brake operators in a super-challenging area that can be hard to adapt to i.e. bending complicated parts with many bends on multi-staged setups. Thankfully, state-of-the-art software and a single, knowledgeable person can take the most challenging parts (tooling, sequence, creativity) out of the equation.

Having a good relationship with the designers is also important. Designers can sometimes come up with concept drawings that are nearly impossible or extremely hard to bend in practice. If you have a good relationship with them, it is easier to work together when it comes to specing parts so that the geometric tolerances are able to be produced within reasonable tolerances. Often their systems are set for machined parts and the same tolerance setup ends up applied to sheet metal projects which aren’t able to be achieved with press brakes.

About EVS Metal

EVS Metal is an American precision sheet metal fabricator headquartered in Riverdale, NJ. Our machinists and operators utilize the latest technology to cut, bend and finish stand-alone items as well as parts for integration or assembly into more complex products. EVS Metal’s four ISO 9001:2015-certified locations comprise over 250,000 square feet of vertically-integrated manufacturing space and feature the most modern equipment available, from lasers and CNC machining centers to automated powder coating lines.

We serve a diverse customer base across North America, providing a range of services from quick-turn prototypes to high-volume production runs. Request a personalized metal fabrication quote online or call 1-888-9EVSMET to speak with a specialist today.